JAPAN’S ability to screen wood product compliance through a government-audited certification program sets a high standard that Australian authorities could well emulate, EWPAA acting CEO Andy McNaught said.

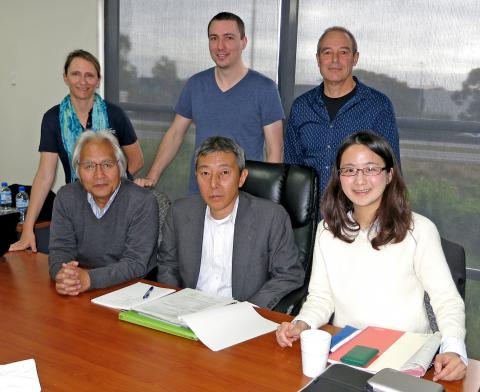

Representatives of the Japanese Ministry of Agriculture, Fisheries and Forestry (MAFF) were in Brisbane recently for their annual audit of the EWPAA JAS (Japanese Agricultural Standard) certification program.

Each year, government officials from MAFF or the Food and Agricultural Materials Inspection Centre witness EWPAA JAS auditing at a member mill and undertake a three-day process and document review of EWPAA’s JAS certification activities.

The Engineered Wood Products Association of Australasia is one of only three JAS foreign certification bodies outside Japan, and the only English-speaking auditor for the program.

The Japanese representatives also visited New Zealand to witness an audit conducted by EWPAA at one of the JAS certified facilities there.

Mr McNaught praised the contribution made to the EWPAA JAS program by laboratory manager Suzie Steiger and quality systems engineer Andrew McLaughlin.

“They’re right across this,” Mr McNaught said.

“Suzie manages all testing of Japanese samples in the Brisbane laboratory and Andrew has undertaken responsibility for the JAS certification, which requires a sound understanding of the Japanese process, which can be quite complex.”

Mr McNaught said the Japanese audit confirmed that EWPAA continued to run a certification program that met all the requirements of JAS.

He said EWPAA member products met three critical requirements – safety during construction; performance of buildings in extreme weather conditions; and air quality with very low or zero emissions.

“The example for Australian authorities is that the Japanese government requires every structural element going into a building has passed a rigorous certification process,” Mr Naught said.

“This government-level of certification demands that framework of every building in Japan is up to scratch.

“This contrasts dramatically with the system in Australia which has to rely on industry self-regulation.”

Mr McNaught said Australia’s system evidently was not working.

“Proof of this is evident in the number of non-compliant products in the marketplace,” he said.

Photo: Happy with JAS audit in Brisbane: Hiroto Yokoshima, chief inspector, JAS conformity assessment division, Japanese Food and Agricultural Materials Inspection Centre, Masatoshi Tomoi, EWPAA’s technical representative in Tokyo, and Yuko Shimoda, assistant technical staff, JAS conformity assessment division, with EWPAA staff Suzie Steiger, laboratory manager, Andrew McLaughlin, quality systems engineer, and Andy McNaught, technical manager and acting CEO.