The Engineered Wood Products Association of Australasia will continue in its commitment to product certification and conformance credentials of building materials entering the market.

The Engineered Wood Products Quality Committee meeting in Brisbane this week reviewed its agenda to maintain rigorous, ‘watertight’ standards to ensure products are safe and absolutely fit for purpose – an ongoing commitment in the face of increasing risks of sub-standard building materials entering the Australian market.

The Quality Committee includes representatives with expertise from across the timber supply chain and specifier communities. The meeting, chaired by Dr Harry Greaves, focused on presentations by EWPAA CEO Dave Gover, Laboratory Manager Suzie Steiger, and Quality Systems Engineer Andrew McLaughlin.

EWPAA’s laboratories at Eagle Farm are accredited by the National Association of Testing Authorities (NATA) and test EWPAA certified products for a full range of structural and physical properties and for formaldehyde emissions and bond quality.

Samples from member plywood, LVL, particleboard and MDF mills are tested daily. The certification schemes are independently accredited by the Joint Accreditation System of Australian and New Zealand (JAS-ANZ).

“Through manufacturing innovation, robust quality control, and adherence to Australasian product standards, the wood products industry is committed to providing a reliable, sustainable, and renewable material for building construction” EWPAA CEO Dave Gover said.

He said EWPAA was positioned to expand its influence as a high-profile and respected industry organisation and certifier of conforming timber products.

“Our priorities in developing and strengthening markets include on-going measures to ensure products used in Australia comply with Australian standards,” Mr Gover said.

“We accept that imports are a reality, but there must be a level playing field and products used in Australian buildings must comply with Australasian standards. Structural safety and the health and well being of building occupants is essential. The EWPAA brand is a mark of confidence that a timber product meets these requirements.

“The EWPAA and its members have been long-time advocates of product conformance and honest branding of products.”

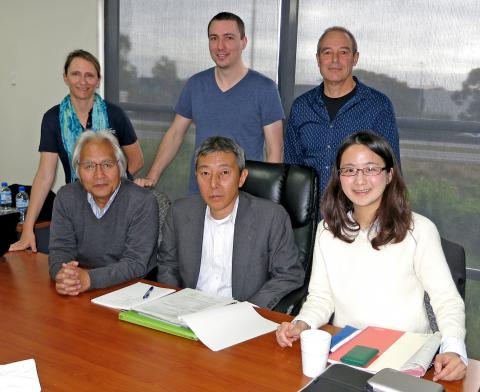

Photos:

Members of the EWPAA technical committee ..

- Dr Michael Kennedy, Department of Agriculture and Fisheries, Brisbane,

- Andrew McLaughlin, EWPAA quality systems engineer,

- Frank Moretti, Gunnersen, Melbourne,

- Dave Gover, CEO, EWPAA, and

- Jim Zacharin, Cabinet Timbers, Moorabbin, Vic.

Technical committee discussions at EWPAA offices and laboratory in Eagle Farm ..

- Paul Neilson, quality systems expert, Brisbane,

- Suzie Steiger, EWPAA Laboratory Manager,

- Dr Harry Greaves, HG Consulting, Melbourne (meeting chairman), and

- Peter Juniper, Juniper Consulting, Melbourne.